Electrolytic Hard Chrome Plating

Thermal Spray Coatings

- Flame Spray

- Spray and Fuse

- HVOF Spray

- Plasma Spray

- Flame Wire Spray

- Arc Wire Spray

Machining

Cylindirical Grinding

Onsite Grinding and Coating

Super Finish Polishing

Sand Blasting

Measurement and Control

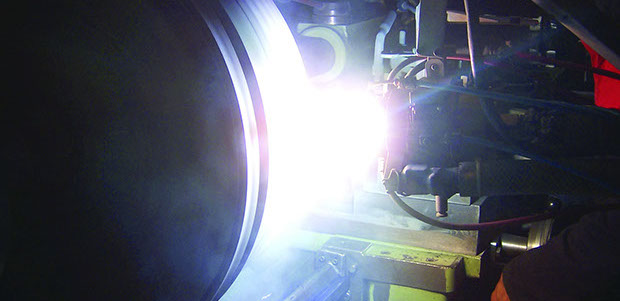

By passing through strong electric arc in the spray gun, noble gases ( argon and hydrogen ) ionizes and forms a plasma flame with up to 10000 °C core temperature. Directed through this flame thermal powders are sprayed with high velocities.

Extreme core temperature plasma flame can easily melt hard-to-melt materials like ceramics thermal dusts and bond them to main material strongly.

In the coating period distortion and dimensional deformation is avoided by controlling the temperature of work piece.

In plasma spraying, thermal powders with various features are used.

- Ceramics (aluminium oxide, titanium oxide, chrome oxide, zirconium oxide)

- Carbides (tungsten carbide, chrome carbide)

- Metal & metal mixtures ( nickel, iron, aluminium, cobalt, copper, molibdenum, titanium based thermal dusts )

- Cermets (metal and ceramic mixtures)

Plasma spraying applications are widely used in industrial processes. These applications provide solutions for wear problems, high temperature corrosions, acid and basic environments, thermal barrier forming.

PLASMA SPRAY

Steel Industry

Paper Indusrty

Synthetic Yarn and Fiber Industry

Steel Wire and Cord Industry

Energy Sector

Rubber and Plastic Industry

Petrochemical Industry

Aluminium Industry

Machinery Industry

Drilling Industry

Textile Industry

Automotive Industry

Copper Wire and Cable Industry

Food Industry

Synthetic Fertilizer Industry

Mining Industry

© 2019 ELKAP All Right Reserved

Contact Us:

ADRESS:

Hanlıköy Mahallesi 15. Sokak No: 21 54580

Arifiye, SAKARYA

PHONE:

+90.264.2751387

+90.264.2763355

+90.264.2769773

FAX:

+90.264.2755678

EMAIL:

elkap@elkap.com.tr

elkap@elkap.com