Electrolytic Hard Chrome Plating

Thermal Spray Coatings

- Flame Spray

- Spray and Fuse

- HVOF Spray

- Plasma Spray

- Flame Wire Spray

- Arc Wire Spray

Machining

Cylindirical Grinding

Onsite Grinding and Coating

Super Finish Polishing

Sand Blasting

Measurement and Control

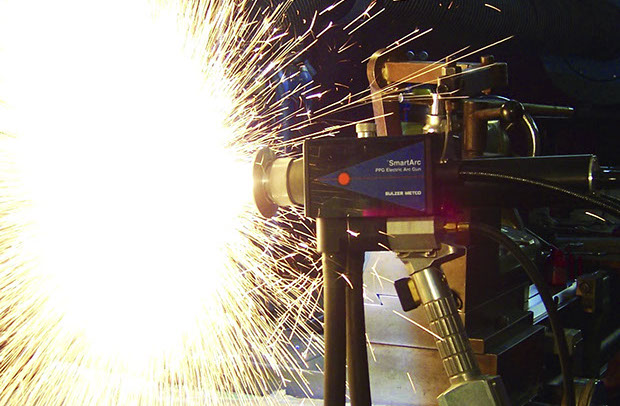

ARC WIRE SPRAY

The contact of wires from opposite poles in the spray gun, creates an electric arc. With this arc, wires melt and dissolve into particles. Coating is achieved by the spray of melted or half melted wire pieces with pressured air.

As coating material, pure metal and metal alloy wires are used. (carbon steels, alloy steels, stainless steels, aluminium, copper, bronze, cobalt, nickel, molibdenum, tin and zinc)

n the coating period distortion and dimensional deformation is avoided by controlling the temperature of work piece.

Above 5mm coating thickness can be obtained with this system. High roughness coatings can be achieved.

Electric arc wire spray coatings brings various advantages to the main material:

- Corrosion resistance

- Obtaining bonding and rough surface

- Good electric and heat conductivity

- Better oxidation and wear resistance

- Higher service temperature

- Higher hardness

- Repairing and diameter restoration

Steel Industry

Paper Indusrty

Synthetic Yarn and Fiber Industry

Steel Wire and Cord Industry

Energy Sector

Rubber and Plastic Industry

Petrochemical Industry

Aluminium Industry

Machinery Industry

Drilling Industry

Textile Industry

Automotive Industry

Copper Wire and Cable Industry

Food Industry

Synthetic Fertilizer Industry

Mining Industry

© 2019 ELKAP All Right Reserved

Contact Us:

ADRESS:

Hanlıköy Mahallesi 15. Sokak No: 21 54580

Arifiye, SAKARYA

PHONE:

+90.264.2751387

+90.264.2763355

+90.264.2769773

FAX:

+90.264.2755678

EMAIL:

elkap@elkap.com.tr

elkap@elkap.com